Custom making an open design slat table

For this custom build, I am working some sapele and quarter-sawn white oak into an open slat design coffee table. The dimensions this table worked out to be would actually work as a sitting bench as well (I did sit on it prior to finishing and it held my weight and did not sag or creak).

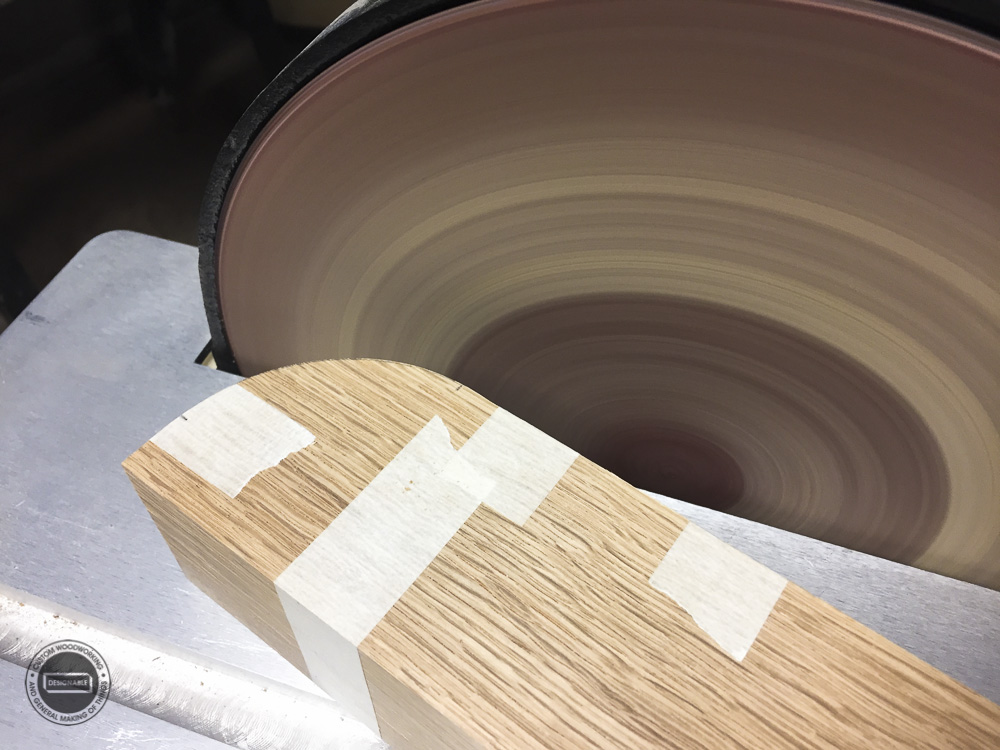

I had in my mind to do something different than the normal squared corners of other similar designs. Shaping the ends to a round softened the look and gave it a better visual interest. carrying that round over to the leg foot lightens the bulk and ties the two together.

Festool domino tenons, along with stainless steel screws from the bottom side, were used to construct the leg assemblies. The sapele top and the leg assemblies were then bonded together, all at once, using West Systems epoxy and oak dowels driven thru the ends, hidden by the two outer slats (using the epoxy gives a longer working time and allows for adjustment when clamping the pieces together). This produces a clean, untouched look as well as mechanical strength.

Pre-shaping the corner joints really saved a lot of time in getting the finger-jointed corner blended to a smooth consistent roundness. I used a combination of my belt sander with 60 grit to quickly knock down any unevenness, followed by 80 and 100 grit on the random orbit sander to smooth it all out, and lastly, hand sanding the entire piece with 120 grit (btw, Carborundum brand {premier red dri-lube aluminum oxide resin paper} sandpaper is phenomenal – it cuts quickly, doesn’t clog up and lasts a very long time. My local wood supplier carries it in 9×11 sheets of various grits up to 6000).

A small round over was added to all edges.

Rubio Monocoat Pure Oil

Finishing the slat table, I chose to apply Rubio Monocoat, a single-coat application oil and wax product, for its ease of use, durability and matte sheen. Spraying or brushing this slat design with a conventional poly/lacquer/oil finish would have been a nightmare full of runs and/or dry spots and would have taken quite a bit of time to complete since those other finishes typical require multiple coats. Rubio Monocoat is 1 coat and done.

With Rubio Monocoat, runs and overlap is essentially eliminated during the application process (see the process in action in my walnut wedge video). A trowel or squeegee helps to quickly cover large flat areas. Spraying is also an option with Rubio Monocoat.

Video production and partial photo credit: Upheval www.upheval.com

* I received the Rubio Monocoat product for free in exchange for my producing a video of it in use. My opinions about the product are mine and are not influenced by the brand.